Apple iWatch Likely to Feature Sapphire Display from GT Advanced Technologies by Matt Margolis

Apple’s iWatch patent was granted on February 21, 2013 under the name BI-STABLE SPRING WITH FLEXIBLE DISPLAY. One clear takeaway is Apple wants this device to have a flexible display and watches need to be durable to take a licking and keep on ticking. The toughest thinnest flexible display I can think of is sapphire laminate courtesy of GT Advanced Technologies via their Hyperion tool.

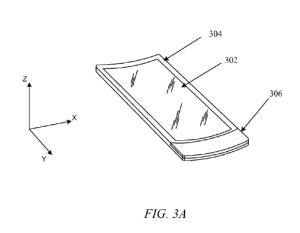

A wearable accessory device is disclosed. The wearable accessory device includes a flexible display coupled to a bi-stable spring. Coupling the display to the bi-stable spring allows the accessory device to be easily worn in a number of convenient locations.

A wearable video device arranged to be worn by an end-user, comprising: a flexible substrate having a flat state and a curled state; a flexible display disposed upon a first surface of the flexible substrate, wherein in the curled state the flexible substrate conforms to an appendage of the end-user, the flexible substrate further comprising: an electronic module in communication with the flexible display, the electronic module providing information to the display, at least a part of which is presented in real time for presentation by the flexible display; and a mechanism for detecting an end portion of the flexible display, the detection for adjusting the arrangement of information shown on the flexible display to match the size of the appendage the wearable video device is mounted on.

Sapphire Laminate Patent Awarded September 2013

Apple was awarded a sapphire laminate patent on September 12, 2013. The patent is very detailed and goes over various forms, uses and assembly options. The patent lists sapphire laminates as a potential cover for nearly everything from phones to watches. The abstract and a key a claim are represented below:

Various sapphire and laminate structures are discussed herein. One embodiment may take the form of a sapphire structure having a first sapphire sheet with a first sapphire plane type forming the major surface and a second sapphire sheet having a second different sapphire plane type forming the major surface. The first and second sapphire sheets are fused together to form the sapphire structure.

0022] Turning to FIG. 1, an example electronic device 100 is illustrated in which a sapphire structure or laminate may be implemented. For example, a sapphire laminate 102 may be utilized as a cover glass and/or back plate of the device 100. Additionally, or alternatively, a sapphire laminate may be utilized as a cover and/or lens for a camera of the device. It should be appreciated that the sapphire laminates may be utilized in various different devices. For example, they may be used for windows, mirrors, cover glass, lenses and so forth in cameras, computers, mobile devices, watches, display devices, touch screens and clocks among other things.

Apple Posts Sr. Module Process Engineer Positions December 2013

As the world was prepping for new year’s eve celebrations Apple was preparing for their iWatch product ramp up. On December 31st, Apple posted a Sr. Module Process Engineer position located in Taiwan. The job description indicates that this “role will serve as a focal point in the design and process development of advanced key modules from concept stage to high volume ramp up“. Additionally, under key qualifications the position calls out “experiences in developing and manufacturing high volume display products“. Lastly, the key qualifications “include back-end process in flat panel industry, including bonding, laminate and module design“.

My takeaways: The position is focused on taking a key module (device) from concept to high volume product ramp, which tells me this product has yet to be mass-produced. The position is focused on displays (due to experience developing high volume display products). The unique experience with flat panel industry, bonding and laminate and module design is very intriguing. Laminates are super thin pieces of substrate, bonding is the process to fuse/epoxy laminates to a substrate and lastly back-end flat panel industry would give someone experience wedging material between two thin substrates. For example, back-end process experience with LCD flat panels would give someone experience placing liquid crystals between two electrically conducting plates. Is it possible that solar panels would be placed between two electrically conducting plates of sapphire laminates in lieu of liquid crystals?

My conclusion: this position is for a new product (iWatch), that will feature a new type of laminate display (sapphire) and is on the verge of entering the high volume product ramp phase ahead of a 2014 release.

Sr. Module Process Engineer Job Description

Individual in this role will serve as a focal point in the design and the process development of advanced key modules from the concept stage to the high volume product ramp.

Key Qualifications

- The idea candidate will need to have 3 years of hands-on experience and proven track record in the design and development of the module process & its integration, or the back-end process in flat panel industry, including bonding, lamination and module design.

- Demonstrated ability to perform DOE, SPC and failure analysis is a must. Experiences in developing and manufacturing high volume display products are preferred.

- Excellent written & verbal communication skills and people skills are required.

- The willingness and ability to travel to Asia are also required.

- Education:

- Ph.D. degree in Physics or Mechanical Engineering or MS degree

GT’s One of a Kind Sapphire Laminate Technology

GT Advanced Technologies acquired Twin Creeks Technology late in 2012 and one of their first primary focuses was to “to pursue the development of thin sapphire laminates for use in applications such as cover and touch screen devices”. The Hyperion ion implanter machine acquired from Twin Creeks can cut ultra thin wafers (25 microns thick) out of silicon, silicon carbide, sapphire, germanium and other crystalline materials. How thick is 25 microns? The laser sliced sapphire home buttons on the iPhone 5s measure 170 microns thick, which is nearly 7 times the thickness of the sapphire laminates that can be sliced by GT’s Hyperion. The Hyperion machine takes a thick block of crystalline sapphire, blasts it with hydrogen ions and exfoliates a 25 micron layer thick sheet of sapphire from the block. The process is repeated over and over until the block is completely separated. As of November 2013, GT expected the pace of the development with Hyperion to accelerate. Hyperion is expected to be commercial ready by 2015, which will also require GT to begin assembly of Hyperion in larger numbers sooner rather than later.

iWatch Sapphire Laminate Fact List

- November 2012 GT acquires Twin Creeks and focuses its pursuit on sapphire laminates for use in cover and touch screens

- September 2013 – Sapphire Laminate Patent was awarded to Apple (filed March 2013)

- November 2013 – Apple signed a $578m contract with GT Advanced Technologies to make sapphire material. Additionally, in GT’s 10-Q they informed investors that the, “Company expects to pursue the development of thin sapphire laminates for use in applications such as cover and touch screen devices”.

- November 2013 – GT updated investors that their Hyperion machine, one of a kind laminate (sapphire) machine is in pre-production. In addition, the Hyperion technology pace of development was expected to accelerate as the company has targeted the technology for commercial use in 2015.

- December 2013 – Apple posted several Sr. Module Process Engineer positions across the globe.

- Focus on taking advanced key modules from the concept stage to high volume product ramp.

- Requires experience with laminates, flex bonding and flat panel industry.

- Requires experience with high volume display products.

- Individual must be willing and ability to travel to Asia

- The iWatch assembly is expected to be performed in Asia

Conclusion:

Given the expected iWatch display size (2 x 2 inches) and unit sales (10-20m in 2014), I believe the iWatch product launch would be a perfect way to utilize GT’s Hyperion technology to mass produce sapphire laminate displays. Furthermore, could the Hyperion technology, which was originally for created for solar cells, be the technological bridge that enables GT to provide solar cells across Apple’s portfolio of iDevices?

Full Disclosure: I am long GTAT and have no plans to buy or sell any holdings in the next 72 hours,

Reblogged this on Tech Talon.

LikeLike